Visit Barwell at K 2025 this October

September 22, 2025

September 22, 2025

Come and meet the Barwell team in Hall 11 at Stand C56 and see some of our ground-breaking rubber processing machinery with your own eyes!

K is the world’s number one plastic and rubber exhibition. It will take place from October 8th to 15th, 2025, in Düsseldorf. More information on the exhibition and how to book tickets can be found below.

We’re looking forward to connecting with you at the exhibition to discuss how we can help you improve and future-proof your polymer production and stay ahead of your competitors.

Don’t miss this opportunity to explore our latest advancements in rubber processing and find out how we can support your growth. You will have a chance to discuss your current and future rubber processing machinery requirements, as well as find out how to receive lifetime service, support and genuine spare parts from our expert team.

We will be sharing our space with our co-exhibitor, Prescott Instruments.

Machines featured on our stand

At the K show, we will launch a revolutionary stand-alone auto-weighing rubber strip cutter machine, which allows you to harness the ability to cut strips by weight or length with high accuracy.

It also provides automatic separation of approved strips and rejected strips, so that only top specification strips exit the machine. Suitable for rolls of rubber only.

Please come to the stand and see it for yourself!

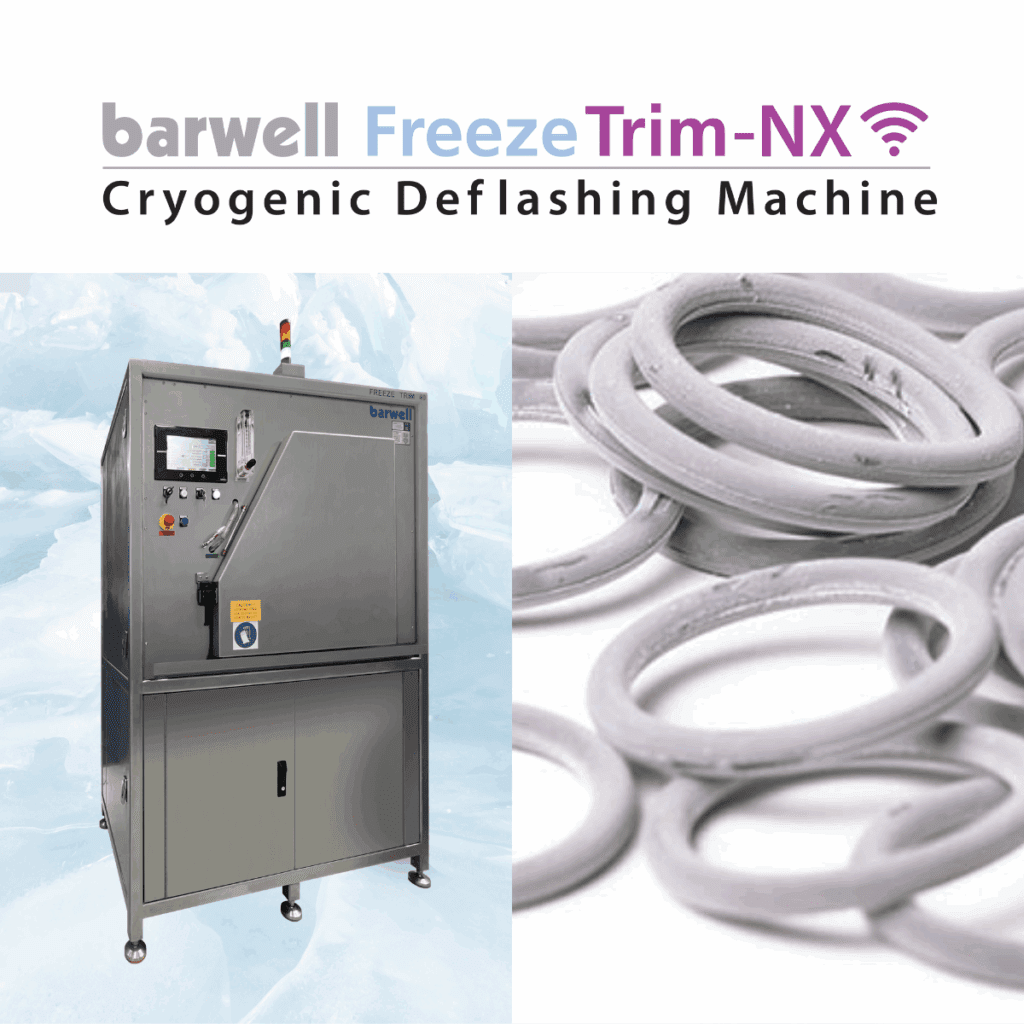

Also on display will be the Barwell BFT-NX cryogenic rubber and plastic deflashing machine, manufactured in stainless steel, equipped with advanced connectivity and data analytics, enabling seamless integration into innovative factory eco systems and Industry 4.0 factories.

Please come to the stand and see it for yourself!

We are at the forefront of innovation, manufacturing advanced machinery for the rubber industry.

Features the revolutionary Industry 4.0 Hot feed Ram-style and cold feed Gear Pump / Screw rubber preforming machines and extruders, as well as transformative rubber strip cutting machines and space-saving cooling spiral conveyors.

We also offer energy-efficient compression presses and state-of-the-art high-performance cryogenic rubber deflashing machines, all designed to push the boundaries of what’s possible in the rubber industry.

With Barwell, you’re choosing more than a machine; you’re choosing a lifetime of reliability and expert support. Our machines are built with superior quality and backed by expert service, support and genuine spare parts to ensure optimum performance.

Regular maintenance with Barwell not only reduces processing time and costs but also improves production quality and extends machine life.